How Rigid-Flex PCBs Provide the Perfect Balance of Flexibility and Stability

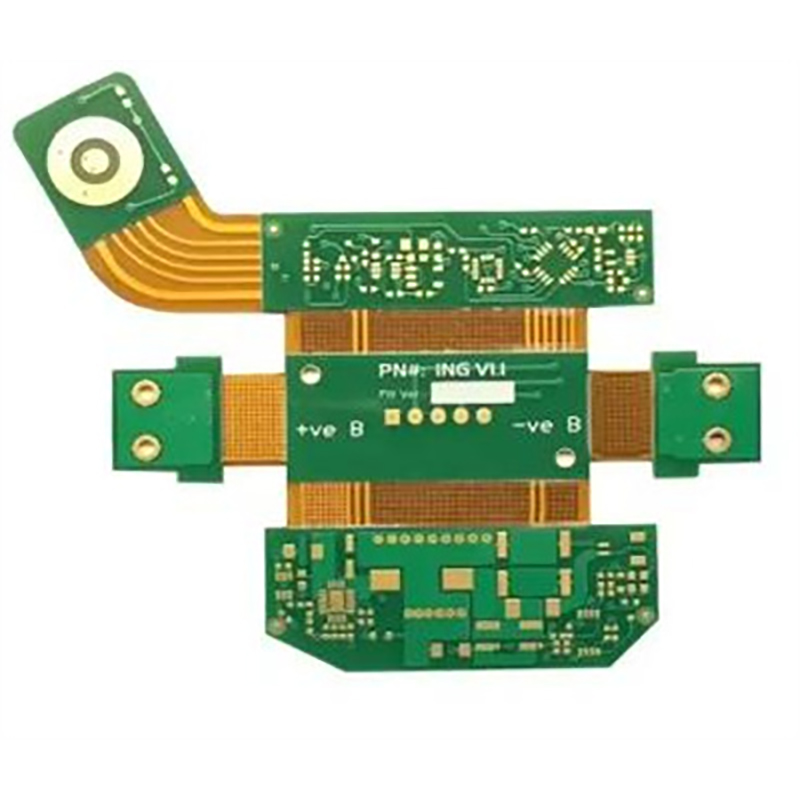

Rigid-flex PCBs are unique because they blend the best features of rigid and flexible circuit boards. They have hard parts that keep them stable and soft parts that allow them to bend. Think of it like a bendy straw: the hard part keeps the straw from collapsing, while the flexible part lets you drink from different angles. In a similar way, rigid-flex PCBs can fit into small spaces in devices while still maintaining their shape and function. This combination is crucial in many fields. For instance, in medical devices, doctors need equipment that can be easily moved but also has to work perfectly every time. Rigid-flex PCBs can be folded to fit inside machines, ensuring that everything works smoothly without taking up too much room.

Another example is in the aerospace industry. Airplanes have many electronic systems that need to be lightweight but very reliable. Rigid-flex PCBs help achieve this balance. They can be shaped to fit into the aircraft's design, reducing weight and saving space. Plus, they can handle the vibrations and movements that happen when flying. With these boards, engineers can design better, lighter planes without compromising on safety or performance.

The materials used in making rigid-flex PCBs also contribute to their flexibility and stability. They are made from special plastics and metals that allow for bending while also being strong enough to support heavy components. This means that engineers can pack more technology into smaller spaces without worrying about breaking anything. All these features make rigid-flex PCBs an amazing choice for modern technology, allowing devices to be more efficient and effective.

What Makes Rigid-Flex PCBs Ideal for High-Performance Applications?

When it comes to high-performance applications, rigid-flex PCBs stand out for several reasons. First, they are incredibly durable. In high-stress environments like automotive or aerospace, components face extreme conditions. Rigid-flex PCBs can withstand heat, cold, and vibrations without failing. This durability is essential because any failure in these industries can lead to serious problems.

Additionally, rigid-flex PCBs allow for more complex designs. Engineers can create intricate pathways for electricity, fitting more technology into a smaller space. This is especially important in devices like smartphones, where space is limited, and performance is key. By using rigid-flex PCBs, designers can incorporate advanced features like high-resolution displays and powerful processors without making the device larger.

Another advantage is the reduction of assembly time. Traditional wiring can be complicated and time-consuming to install. But with rigid-flex PCBs, many connections are made in one piece, speeding up the manufacturing process. This efficiency not only saves time but also reduces costs, making it more affordable for companies to produce high-tech devices.

Finally, rigid-flex PCBs enhance reliability. Fewer parts mean there are fewer chances for something to go wrong. This reliability is critical in high-stakes environments like medical devices, where lives depend on precise function. When you choose rigid-flex PCBs, you are investing in technology that provides peace of mind, knowing that it can handle whatever challenges come its way.

At Engine, we are excited about the future of rigid-flex PCBs and how they will continue to shape the world of technology. They truly bridge the gap between flexibility and stability, making them a smart choice for many applications.

Rigid-flex PCBs are special types of circuit boards that combine both rigid and flexible parts. This unique design helps them solve many common problems in electronics. One of the big issues with regular circuit boards is that they can be too stiff. This means they can break easily when bent or twisted. On the other hand, flexible PCBs can bend and twist, but they might not be strong enough for certain uses. Rigid-flex PCBs bring the best of both worlds together. They have rigid sections that provide strength and stability, while flexible parts allow them to bend and fit into tight spaces. This makes them perfect for devices that need to be compact and portable, like smartphones and tablets. When using rigid-flex PCBs, engineers can create smaller and lighter devices without sacrificing performance. Moreover, these circuit boards can help reduce the number of parts needed in a device. Instead of using separate rigid and flexible boards, engineers can use just one rigid-flex PCB. This reduces the risk of parts getting disconnected, which can lead to device failures. Rigid-flex PCBs also make it easier to design complex electronic systems, as they can fit into places where traditional boards cannot. At Engine, we focus on creating high-quality rigid-flex PCBs that meet the needs of modern electronics, making devices more reliable and efficient.

Rigid-flex PCBs are commonly used in many modern technologies. You can find them in various devices that people use every day. For instance, in smartphones, rigid-flex PCBs allow for a slim design while still providing all the necessary functions. They help connect different parts of the phone, like the screen, camera, and battery, in a compact way. Another place rigid-flex PCBs are found is in medical devices. These devices often need to be pcb small and lightweight while still being very reliable. For example, heart monitors and other medical equipment can use rigid-flex PCBs to fit inside the small spaces of a patient’s body or to be worn easily. Rigid-flex PCBs are also popular in aerospace technology. Planes and satellites require durable and reliable electronics that can withstand tough conditions. The combination of flexibility and strength in rigid-flex PCBs makes them ideal for these applications. In addition to that, consumer electronics like wearables, cameras, and gaming consoles also benefit from this technology. At Engine, we understand how important it is to use rigid-flex PCBs in these devices. They help make technology smaller, lighter, and more efficient.

Using rigid-flex PCBs can also help companies pcb circuit board save money and improve how they make products. When manufacturers use rigid-flex PCBs, they can cut down on the number of parts they need to buy and assemble. This can lead to lower production costs because fewer materials are required. For example, instead of having to order separate rigid and flexible boards, companies can just order one type of rigid-flex PCB. This means less time spent on assembly and fewer chances for mistakes. Additionally, since fewer parts are involved, the chances of something going wrong during the manufacturing process are reduced. It also makes it easier to manage inventory since companies only need to keep track of one kind of board. Furthermore, rigid-flex PCBs can speed up the production time. Because they are designed to fit seamlessly into devices, engineers can work more quickly and efficiently. This pcba circuit board means products can get to market faster. At Engine, we strive to provide rigid-flex PCBs that not only meet high standards of quality but also help our clients save money and improve their manufacturing processes. Overall, rigid-flex PCBs are a smart choice for companies looking to enhance their electronics while keeping costs down.