What Makes It Essential for Precision Robotic Welding?

The SmartEye Laser Tracker is key for precision robotic welding because it can track the position of the welding tool with great accuracy. This is vital since even a tiny mistake in the weld position can lead to weak joints or faulty products. The SmartEye uses laser beams to measure exact locations and angles, allowing the robot to adjust itself in real-time. This means that if a part moves slightly during the welding process, the robot can quickly adapt and keep welding in the right spot. For example, think about building a car. If a robot has to weld two metal pieces together and one of those pieces shifts a bit, the SmartEye Laser Tracker ensures that the robot adjusts immediately, preventing any bad welds that could cause problems later. Additionally, using this tool helps reduce wasted materials. If the robot welds correctly each time, there are fewer mistakes, and companies save on costs. This also helps the environment by creating less waste. Companies using MINYUE’s SmartEye can improve their production processes and deliver better final products to customers.

Common Usage Issues in Robotic Welding and How SmartEye Addresses Them

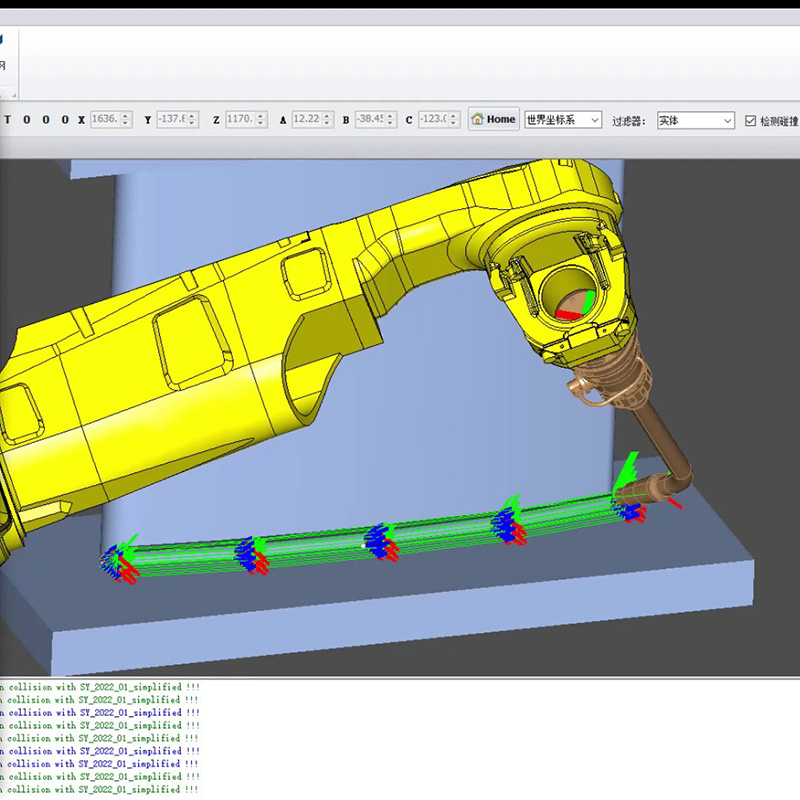

Robotic welding comes with its challenges. Sometimes, parts might not be in the same position as expected, leading to poor-quality welds. Temperature changes, vibrations, or even the wear of materials can mean that the robot doesn’t always have the exact location for welding. That’s where the SmartEye Laser Tracker shines. It can help solve these problems by constantly checking the position of the pieces being welded. If something goes wrong, the SmartEye updates the robot instantly, giving it the right coordinates for precise welding. Furthermore, the SmartEye can reduce downtime in the production line. Many welding errors mean stopping the machine to fix or re-adjust. With the SmartEye in place, businesses can keep the robots running smoothly. It provides feedback that helps the robot stay on track and weld accurately even if the environment changes, like working in different temperatures or with different materials. MINYUE knows how important it is for companies to not lose time and money, and the SmartEye sure helps fix these common issues. This technology supports workers too, making their job easier as they can rely on precise welding, and it helps businesses meet growing demands more efficiently.

In this fast-paced world, having reliable tools like the SmartEye Laser Tracker is necessary for the future of robotic welding. With MINYUE's commitment to innovation, companies can remain competitive and efficient in their production processes.

What Wholesale Buyers Should Know About SmartEye Laser Tracker Benefits

When looking for high-tech tools for robotic welding, wholesale buyers should pay close attention to the SmartEye Laser Tracker. This device brings many benefits that can make welding jobs much easier and more precise. First, the SmartEye Laser Tracker helps robots see where they need to weld, making sure everything is lined up just right. This means that the welds are stronger and last longer. For companies that buy in bulk, this technology can save time and money because it reduces mistakes. When mistakes happen, it can cost a lot to fix them, and customers might be unhappy with poor-quality work. With the SmartEye Laser Tracker, workers can get more done in less time, increasing productivity. This means that businesses can meet their deadlines and keep their customers happy.

Another great benefit of the SmartEye Laser Tracker is that it adapts to changes very quickly. In the world of welding, sometimes parts are not exactly the same size or shape. The SmartEye Laser Tracker can easily adjust to these differences, which keeps the robot working correctly. This flexibility is essential for businesses that work on different projects. With this technology, buyers can be sure that their robots will perform well, no matter what kind of job they have to do. Plus, using the SmartEye Laser Tracker can help reduce the need for extra workers who check if everything is correct, saving even more money. Overall, understanding the benefits of the SmartEye Laser Tracker can help wholesale buyers make smart choices that improve their welding processes.

How to Optimize Robotic Welding Processes with SmartEye Laser Tracker

To make the best out of the SmartEye Laser Tracker, it is essential to know how to use it correctly in robotic welding processes. First, buyers should ensure the device is properly installed and set up. This is important for getting accurate readings and making sure that the robot can see everything it needs to weld. The SmartEye Laser Tracker should be placed in the right position, so it can track the welding points without any obstacles in the way. Once it is set up, workers must regularly maintain the device. Keeping it clean and checking that it’s working correctly helps avoid problems during welding jobs.

Next, training workers to use the SmartEye Laser Tracker is very important. Employees should understand how to read the information it provides and how to respond quickly if there is an issue. It is also helpful for workers to learn how to adjust settings based on the specific job they are doing. This knowledge ensures that each welding project is done with the most precision possible. By empowering workers with the right training, companies can use the SmartEye Laser Tracker to its full potential, leading to better results.

Another great way to optimize robotic welding processes is by analyzing the data collected by the SmartEye Laser Tracker. This device keeps track of how well the robots perform during welding jobs. By reviewing this information, companies can find areas for improvement. This analysis allows businesses to make quick changes when needed, ensuring everything runs smoothly. Regular reviews of the data can lead to even more efficiency, helping to drive down costs and increase overall output. Companies that use the SmartEye Laser Tracker in this way can significantly enhance their robotic welding operations, leading to higher quality products and happier customers.

What Are the Key Features of SmartEye Laser Tracker That Attract Wholesale Buyers?

Wholesale buyers are drawn to the SmartEye Laser Tracker because of its impressive features that enhance robotic welding. One of the standout features is its high welding robot precision. The SmartEye Laser Tracker can measure small distances and angles with exceptional accuracy. This means that when robots weld, they can do it exactly where needed, which leads to stronger and more reliable welds. For wholesale buyers, investing in a product that offers such precision is a smart choice because it reduces the chances of mistakes and the costs associated with them.

Another key feature is its adaptability. The SmartEye Laser Tracker is designed to work in various environments and can adjust to different sizes and shapes of parts. This flexibility is important for companies that have diverse projects, as it allows workers to switch between tasks without needing to recalibrate everything. This saves time and robo welder keeps productivity high.

The SmartEye Laser Tracker also provides real-time feedback. This feature allows workers to see what is happening during the welding process instantly. If something goes wrong, they can fix it right away rather than waiting until the job is done. This fast response time helps maintain quality and ensures that the welding meets industry standards.

Lastly, the ease of use makes the SmartEye Laser Tracker attractive to wholesale buyers. It has an intuitive design that allows workers to learn how to use it quickly. This is very important because it minimizes the time for robotic welding arm training and lets businesses start using the tool almost immediately. Overall, the unique features of the SmartEye Laser Tracker make it an appealing choice for wholesale buyers looking to enhance their robotic welding processes. By investing in this advanced technology from MINYUE, companies can improve efficiency, quality, and ultimately their bottom line.